The Morarjee Textiles means sustainable air, water, earth, environment, health, education, business, jobs etc.

The Morarjee Textiles has integrated sustainability into the established integrated Management System. We are committed to prevention and control of water wastage, air and land pollution. To create a road map for this initiative, we have developed the “Environment Policy".

The Morarjee Textiles strives to minimize the negative impact on the environment by applying innovative thinking to every step of manufacturing process.

Building Eco-friendly practices in daily processes is a part of our culture. This culture inspires us to try to make more from fewer resources and minimize waste in every form. We attempt to contribute to a better environment by reducing water consumption, minimizing wastage and using renewable energy resources over conventional ones.

We take corporate responsibility as a way of life and aim to achieve Zero waste in next 10 years.

Being responsible stewardship of biodiversity of land, soil, air and water, we use BCI cotton which require 14% less water & 23% less pesticides and also use Organic cotton as per customer requirements

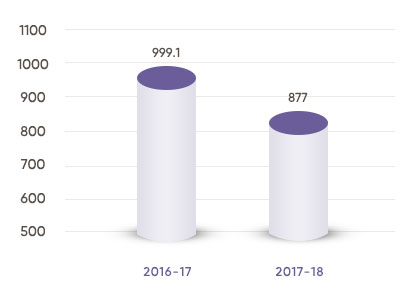

We have identified and implemented ways to reuse and recycle water and to minimize our water footprints. Our water conservation and Recycling initiatives have helped us to lower our dependence on water resources.

We are continuously working to improve our water efficiency and have metering systems across the water distribution network. Our team regularly monitors the metering system.

The MTL has developed a culture of saving Water a Nature Resource by

This has resulted in water saving of 12.2 % less water intake from MIDC.in FY18. No additional water is taken from MIDC even when after increased plant capacity in FY17

We are focused on recharging maximum rain water in to the ground , We have set up Rain Water Harvesting Systems (RWHS) within our premises. Rain water is directed from roof tops through channels and then collected in a collection pit with filter and water is recharged into the ground through bore holes.

1 The textile industry is inherently water intensive and therefore wastewater

generation is considerably high.

Morarjee Textiles has set up Zero Liquid Discharge Plant ( ETP & RO ) of State of Art technology

{Capacity 1400 KLD} to make wastewater reusable and recyclable.

Zero Liquid Discharge Plant 1400 KLD

2 Morarjee Textiles also set up a new STP 200 m3 per day capacity based on Constructed Wet Land Process. It is again a new technology and does not consume any power and its treated water is used for Gardening and flushing.

3 In addition, we have constructed a big u/g storage tank of 2500 KL capacity to collect cooling water from process machines for recirculation and also collect subsoil rain water.

Energy conservation implies reducing energy consumption at the organizational level. Energy conservation differs from efficient energy use, which refers to using less energy for a constant service.

Morarjee Textiles has undertaken a number of measures to reduce energy consumption.

We have Environment Policy, Quality Policy, Health and Safety Policy in Morarjee Textiles, which extends to all the manufacturing units of Ashok Piramal Group.

Climate change, global warming and environmental degradation pose unique challenges as well as opportunities for Morarjee Textiles. We are continually investing in new technologies, implementing process improvements and innovating.

We aim to enrich the local ecosystem, contribute to biodiversity and offset our carbon footprint by creating forests, step by step

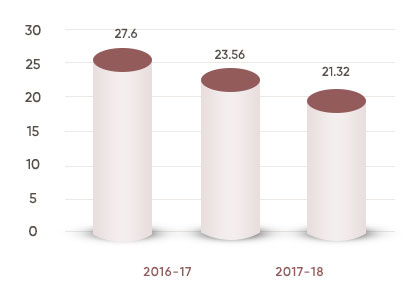

Electrical and Thermal energy conservation measures and efficient running of the machines resulted in reduction in GHG emissions.

We have reduced the GHG footprint up to 9.6% by reducing our energy consumption and fuel consumption. Carbon foot prints tons CO2 equivalent is reduced from 23.56 to 21.3.

We use the right chemicals judiciously and responsibly. It is our constant effort to find substitutes that have a smaller impact on environment.

Environment week, safety week, Water saving week, Energy Conservation week are celebrated every year which includes various activities like Tree plantation, Drawing competition, slogan competition, Quiz competition, Safety pledge, Blood donation etc.

Other noble causes are awareness of menace of drugs, Gutkha and periodic visit of doctors for check-up teeth, eyes, health and HIV awareness etc. in factory premises for welfare of employees.

CSR activities under Urvi Ashok Piramal Foundations.